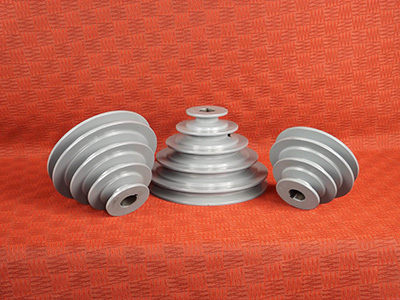

Product Description

Our Services

Product Design Material Selection

Mold Design Mold Making

Bulk Production Logo Printing

Surface Treatment Assembling

Packaging Door to Door Delivery

| Material | EPDM,Silicone,FKM,NBR,NR,SBR,IR,IIR,etc. |

| Color | Black, white, red, green, transparent or any color according to Pantone code |

| Size | As per customer’s requirements |

| Technology | Compression molding, injection molding, vacuum vulcanizing, extrusion |

| Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

| Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

| Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Detail Image

Why Choose Us

Zhongde is a leading manufacture of OEM parts in plastic &rubber parts. Our workers are experienced and professional in international trade.We are always pursuing providing better quality products and more competitive price in shorter period. With a experienced engineer team, production team and Professional sales team.we are confident to help you develop and manufacture your product.

Our Machine

Product Range

Contact Us

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Customized: | Customized |

|---|---|

| Color: | Customized |

| Type: | Rotating Wheel |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | Order Sample For sample price, package information, and logisti

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Can step pulleys be used in both industrial and DIY applications?

Yes, step pulleys can be used in both industrial and DIY (do-it-yourself) applications. Here’s how they are applicable in each context:

1. Industrial Applications:

Step pulleys are widely used in various industrial applications where variable speed control is required. They can be found in machinery such as milling machines, lathes, drill presses, and industrial mixers. In industrial settings, step pulleys provide a reliable and cost-effective solution for adjusting the speed of rotating components, allowing for precise control and optimal performance.

2. DIY Applications:

Step pulleys are also suitable for DIY enthusiasts and hobbyists who work with machinery or equipment that requires variable speed control. For example, in woodworking, step pulleys can be used in DIY table saws, band saws, or sanders to adjust the cutting or sanding speed according to the material and desired finish. They can also be employed in DIY metalworking projects or other applications where adjustable speed is beneficial.

3. Advantages for DIY Applications:

Using step pulleys in DIY applications offers several advantages. They provide a relatively simple and affordable means of achieving variable speed control without the need for complex electronic controls or expensive variable frequency drives. Step pulleys are easy to install and operate, making them accessible to DIYers with basic mechanical skills.

4. Limitations for DIY Applications:

While step pulleys offer flexibility in speed control, they may have limitations in terms of the available speed range and increments compared to more advanced speed control systems. Additionally, the load capacity of step pulleys may be lower compared to heavy-duty industrial machinery, so it’s important to consider the specific requirements of the DIY project and choose the appropriate pulley size and material.

Overall, step pulleys can be utilized effectively in both industrial and DIY applications to achieve variable speed control. They provide a practical and versatile solution for adjusting rotational speed, whether it’s in large-scale industrial operations or smaller DIY projects.

How do you select the right step pulley configuration for a specific task?

Selecting the right step pulley configuration for a specific task involves considering several factors to ensure optimal performance. Here’s a step-by-step guide to help you make the right choice:

1. Identify the Speed Range:

Determine the required speed range for the task at hand. Consider the materials being worked on, the cutting tools or processes involved, and any specific speed requirements for achieving the desired results. This will help you understand the range of speeds needed from the step pulley.

2. Assess the Available Speed Options:

Examine the available step options on the pulley system. Count the number of steps and note their respective diameters. Each step corresponds to a specific speed ratio, allowing you to achieve different speed settings. Evaluate whether the available speed options cover the required range for your task.

3. Consider Speed Increments:

Take into account the speed increments or intervals between each step on the pulley system. Some step pulleys offer finer speed adjustments with smaller increments, while others may have larger jumps between steps. Determine if the available increments align with the level of speed control needed for your task. Smaller increments provide more precise speed adjustments.

4. Evaluate Power Transmission Requirements:

Consider the power transmission requirements of your task. Assess the torque and power demands of the machinery or equipment involved. Ensure that the step pulley configuration you choose can handle the required power transmission without overloading or straining the system.

5. Assess Space and Compatibility:

Evaluate the available space and compatibility with your machinery or equipment. Ensure that the step pulley configuration can be properly installed and integrated into the existing system. Consider factors such as pulley size, shaft diameter, and belt compatibility.

6. Consult Manufacturer’s Guidelines:

Refer to the manufacturer’s guidelines, specifications, and recommendations for the machinery or equipment you are working with. The manufacturer may provide specific guidelines on selecting the appropriate step pulley configuration for optimal performance and compatibility.

7. Seek Expert Advice:

If you are unsure about the right step pulley configuration for your specific task, it is recommended to consult with experts or professionals in the field. They can provide valuable insights and guidance based on their experience and expertise.

By following these steps and considering the relevant factors, you can select the right step pulley configuration that aligns with the speed requirements, power transmission needs, and compatibility of your specific task.

In which industries and applications are step pulleys commonly used?

Step pulleys find widespread use in various industries and applications where adjustable speed control is required. Here are some industries and applications where step pulleys are commonly used:

1. Machine Tools:

Step pulleys are extensively used in machine tools such as drill presses, milling machines, and lathes. They allow operators to adjust the rotational speed of cutting tools, enabling precise machining operations.

2. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems often utilize step pulleys in blower motors and fans. These pulleys enable adjusting the speed of the fan to control airflow and temperature regulation.

3. Automotive Industry:

Step pulleys are employed in various automotive applications. They can be found in engine accessories like alternators and power steering systems, where they allow for adjustable speed control.

4. Industrial Machinery:

Step pulleys are used in a wide range of industrial machinery, including conveyors, packaging machines, textile machines, and printing presses. They provide speed variation for different production requirements.

5. Exercise Equipment:

Step pulleys are utilized in exercise equipment like treadmills, stationary bikes, and elliptical machines. They allow users to adjust the difficulty level and intensity of their workouts by changing the speed or resistance.

6. Garage Door Openers:

Step pulleys are commonly found in garage door openers. They enable smooth and controlled opening and closing of garage doors by adjusting the speed and torque applied to the door mechanism.

7. Textile Industry:

In textile manufacturing, step pulleys are used in textile machines such as spinning frames and weaving looms. They provide speed control for various stages of the textile production process.

8. Woodworking Machinery:

Step pulleys are utilized in woodworking machinery, including table saws, band saws, and sanding machines. They enable operators to adjust the speed of cutting or sanding tools for different types of wood and desired finishes.

These are just a few examples, and step pulleys can be found in numerous other industries and applications where adjustable speed control is essential.

editor by CX

2023-09-22